Rubber Stall Mats

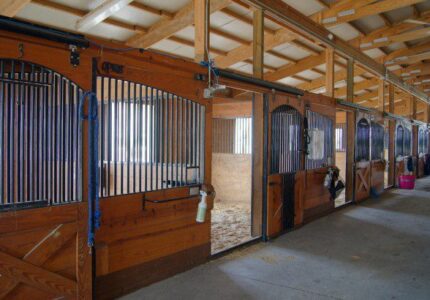

In the equine environment, stall mats are used in to provide a cushioned floor surface that is easy to keep clean.

All of our stall mat products are made using the vulcanization process. In this process, recycled tire rubber is ground into tiny pieces and chemically melted.

The liquid rubber is poured into molds where the mats are formed using carefully controlled heat and pressure. The result is a solid block of rubber that is firm yet resilient and totally waterproof.

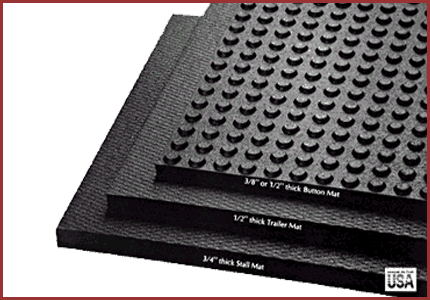

Molded Stall mat products are available in three thicknesses, 3/8″, 1/2″ and 3/4″. These mats come in both interlocking and straight edged versions. We offer premium and budget stall kits from Humane and ProMat. For horses who require extra cushioning in their stalls, we offer a unique stall mattress product from StableComfort. The mattress system offers ultimate cushioning and a sealed top skin that creates a liquid-proof sealed surface.

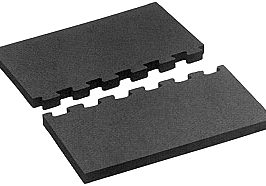

For stalls and other equine applications, the mats are produced in nominal 4′ x 6′ or 2′ x 6′ rectangles. The actual dimensions are slightly smaller, due to trimming that occurs during when these mats are “trued” to create perfectly square edges or when the interlocking tabs are created.

There are multiple surface treatment options. Among the most popular is a micro-diamond texture that provide excellent slip resistance in wet or dry conditions. Other popular textures include “punter-top and pebble-top.

The base of these mats also come in two versions. The standard base if flat. For applications where additional cushioning is required, a “waffle” base is also available. Some products add a series of parallel groves to the bottom of their mats to allow for liquids to drain away quickly.

Some of our Rubber Stall mat suppliers computerized, water jet technology to precisely cut their mats as needed. This process is used for truing and to produce the interlocking edges. For a small additional charge, mats can be cut at the factory to fit a customer’s custom dimensions.